Greetings, community! Today, I want to shed light on an important aspect of measuring runout: the significance of knowing the orders of a runout signal. This knowledge is essential for precision manufacturing, quality control, and optimizing product performance. Let’s dive in and explore why it matters! ????????️

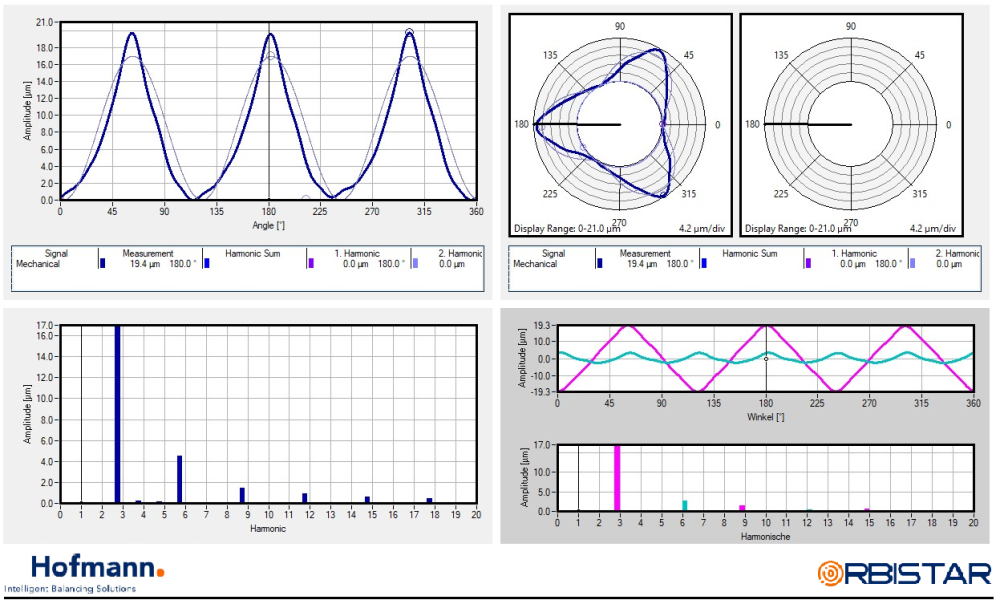

When measuring runout, it’s not enough to simply determine the presence or magnitude of the deviation. It’s equally crucial to understand the orders of the runout signal. The term «orders» refers to the number of full rotations made by the rotating component that contribute to the runout.

Here’s why knowing the orders of a runout signal holds tremendous value:

1️⃣ Identifying Root Causes: Runout signals can result from various factors, such as eccentricity, misalignment, or unbalanced mass distribution. By analyzing the orders of the runout signal, engineers can pinpoint the root causes behind the deviation. This understanding enables targeted corrective actions to be taken, addressing the underlying issues and minimizing the potential for recurring problems.

2️⃣ Characterizing System Behavior: The orders of a runout signal provide crucial information about the behavior and dynamics of the rotating system. Different orders represent different modes of vibration and variations in the rotational path. By studying these orders, engineers can gain insights into system resonances, critical speeds, and potential areas of instability. This knowledge aids in designing robust and efficient systems and mitigating performance issues.

3️⃣ Precision Alignment and Balancing: Understanding the orders of a runout signal helps in aligning and balancing rotating components with precision. By knowing the specific orders contributing to the runout, engineers can determine the required adjustments and corrective measures. This targeted approach ensures optimal alignment and balancing, reducing vibrations, minimizing wear and tear, and enhancing the overall efficiency and lifespan of the machinery.

4️⃣ Troubleshooting and Failure Analysis: When troubleshooting issues related to rotating machinery, knowing the orders of a runout signal is invaluable. It provides critical information for failure analysis and diagnosing potential problems. Engineers can compare the orders of the runout signal with historical data or industry standards to identify deviations or anomalies, facilitating root cause analysis and effective resolution.

5️⃣ Advanced Signal Processing and Analysis: With advancements in technology and data analytics, engineers can apply advanced signal processing techniques to runout measurements. Analyzing the orders of the runout signal using techniques like Fast Fourier Transform (FFT) allows for in-depth frequency analysis, identification of harmonics, and extracting valuable insights from the data. This advanced analysis empowers manufacturers to optimize performance, reduce downtime, and enhance overall product quality.

By embracing the knowledge of runout signal orders, manufacturers can unlock a deeper understanding of their rotating systems, enabling targeted improvements, enhanced performance, and reduced risks of failure.

I’m eager to hear your thoughts and experiences on this topic! How have you leveraged the understanding of runout signal orders in your work? Let’s continue to explore the intricacies of precision manufacturing together! ????????